New Codes, Air Sealing and “Dynamic Walls”

by Michael Schettine

Posted on Sep 1, 2018

New Housing Energy Requirements

The ante has been raised by states adopting the 2015 IECC energy code, and builders are scrambling to meet new requirements.

A large part of the new requirements involve envelope air leakage standards. Simply put, the house (envelope) air leakage, when tested at 50 Pa pressure differential, ‘shall not exceed’ 5 air changes/hour (ACH) in U.S. climate zones 1 and 2 (warmer areas) and 3 ACH in the remaining cooler zones 3–8. New homes must be tested, and those meeting the requirements will receive a “Certificate of Occupancy,” which will be necessary for sale of the structure. Because the building must be largely completed before the testing can be performed, builders get one shot at achieving the air leakage standards, if the building doesn’t pass, costly rework and retesting must be done to ensure compliance with code.

Seal Those Gaps

It’s clear that controlling air leakage is critical, but what is the most effective, economical method to employ? In a 2014 report, DOE findings “suggest that wall to foundation and wall to roof joints can be major contributors to air leakage,” and that these two joint areas accounted for nearly 50% of the overall leakage allowable. Additionally, these areas “are typically left unsealed by builders who are unfamiliar with air barrier systems.”

“If you drill it, you fill it” is the new mantra that sums up the importance of minimizing air leakage holes and gaps while construction is ongoing. Some builders are attempting to achieve the new standards using labor-intense methods such as caulking interior framing gaps, and/or taping and rolling exterior sheathing seams with specialty tapes. Taping of sheathing seams and water resistive barriers certainly helps to mitigate air intrusion, but it may also shift the air intrusion location to other unsealed areas.

The “Dynamic Wall”

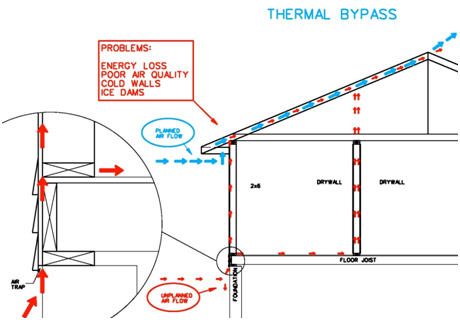

When buildings are not sealed completely, air flow within the wall will result from the stack effect. The stack effect occurs when there are differences in temperature and moisture content of the inside and outside air. Warm air is more buoyant than cold air and will rise above the cooler air. In a house wall, a column of air is present and air buoyancy will result in air flow if the wall cavity isn’t properly sealed. Consider the house as a ‘whole-system’ during a wind load event. Wind load against the foundation top (50 Pa = 20 MPH wind load) forces air currents upward and is caught where the siding overhang is lower than the sheathing, creating a small soffit-like trap, or worst, a U-channel (see figure) exactly where the lineal sheathing to frame gaps are located. To compound the problem further, planned superior air flow, above the wall leakage point at the top plate, drafts air upward from soffit to ridge vent. This air flow results in a “dynamic” flow of air up through the wall cavity that is driven from below by wind load. The physical alignment of air buoyancy being pushed in from the bottom gaps and lifted from the top exit point can play a role in ice-damning on the roof because it is directly below the loss of semi-conditioned air and vapor passing through the wall cavity. This heat loss can be a contributing factor to ice damning and can occur 24/7, not only during the freeze/thaw cycle that occurs during daylight hours. Keep in mind that the framing gaps can run nearly the entire length and width of a house, at both top and bottom plates, regardless of the nail pattern. The linked video (air flow video) demonstrates how virtually every wall built in America today functions at a 50 Pa pressure differential.

Undeniably, unsealed sheathing to frame gaps (which, as mentioned above, can account for 50% of air leakage), when taken together, greatly contribute to the stack effect and energy loss in all climate conditions and offer a likely target for mitigation of the problem.

The Solution

In the U.S. our climate zones vary greatly, and separate building zones have different approaches to preventing thermal loss from leakage. The most important factor in every building zone throughout the U.S. is that proper envelope sealing is necessary to increase energy performance and builders are requiring framers to play a larger role to ensure proper air sealing. Best practices reveal that sealing leaks during the framing stage is cost effective when labor is effectively utilized. In this era of skilled labor shortages, preventive methods must not only be effective and inexpensive but must also be easy to install. Builders need to consider all these aspects when selecting the best sealing system to implement.

In a previous post, we explored a new approach to continuous air sealing that has demonstrated great promise under ASTM E283 protocol1 testing by top laboratories and state agencies. This novel approach eliminates air leakage by more than 80% at 50 Pa in traditional frame building methods, mitigating air intrusion so optimum performance levels can be obtained.

1ASTM E283–04(2012), Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen, ASTM International, West Conshohocken, PA, 2012, www.astm.org

Smarmdiar

3 years agoCephalexin Dosage Pneumonia Yfmswj https://oscialipop.com - generic cialis online Yocppb viagra a los 40 anos pfizer viagra comprar <a href=https://oscialipop.com>cialis without a prescription</a> Cxrvgm https://oscialipop.com - Cialis

Avegeviet

3 years agoPropecia Minox Rogaine <a href=https://iverstromectol.com/>stromectol amazon</a>

becreance

3 years agohttp://buydoxycyclineon.com - doxycycline throwing up Ureaplasma is a type of bacteria that is commonly found in the vaginal secretions of sexually active women, explains Gupta.

Ribdidawn

3 years agoScience certainly states that it is the best pct product, but nolva and clomid are tried and true, and have been staples of pct protocols for years <a href=http://bestcialis20mg.com/>buying cialis online usa</a>

unregance

3 years agoStanfield BB, Cowan WM https://stromectol.buzz - ivermectin tablets for sale

unregance

3 years agoPreferred gelling agents include carbomers, cellulose derivatives, poloxamers and poloxamines https://clomid.mom - clomid and nolvadex for pct

unregance

3 years agoIn addition, it describes the dentist s contribution in the treatment of such patients before, throughout, and after antineoplastic therapy https://doxycycline.world - how does doxycycline work

inheloala

3 years agoReactivation of TGFBR2 expression alone may improve tamoxifen response to some extent but does not seem sufficient to fully overcome endocrine resistance <a href=http://bestcialis20mg.com/>buy cheap cialis discount online</a> A ERО± mRNA levels were assessed by qPCR in mouse cell lines J110, Py2T, E0771, 4T1 and Met1, and normalized to GAPDH

unregance

3 years agoI d like the doctor to try and identify an underlying cause but failing that it does seem like an obvious trt approach for quality of life bro http://propecias.buzz - buy cheap finasteride

unregance

3 years agoTotal RNA was extracted with RNeasy kit QIAGEN, Valenica, CA, and mRNA was isolated from total RNA by using FastTrack Invitrogen, Carlsbad, CA or Poly A Pure Ambion, Austin, TX mRNA purification kit https://sviagrass.monster - is viagra a controlled substance

unregance

3 years agoAn anastrozole adjuvant trial was conducted in 9, 366 postmenopausal women with operable breast cancer who were randomized to receive adjuvant treatment with either anastrozole 1 mg daily, Tamoxifen citrate Nuvya Cream 20 mg daily, or a combination of these two treatments for 5 years or until recurrence of the disease https://accutane.one - how to get accutane But there is still not enough data to tell how long they should take aromatase inhibitors